As many of us BMW enthusiasts have known for a while now, the vehicles brought to the public by BMW have a few key characteristics that set them apart from the typical automobile. Steering sharpness, engine response, crisp brake pedal feel inspire confidence for all those who get behind the wheel of the Ultimate Driving Machine. Another key component has been a comfortable suspension that still provides accurate response to driver inputs. BMW focuses on a package that makes the whole greater than the sum of the individual parts. This is true for all their models from the luxurious executive saloon 7 series models to the entry level 1 series.

The entire package, as designed by the engineers of Munich, is made to compliment the engine. The transmission ratios are matched to the torque curve so that fuel economy is matched with a perfect balance of sporty performance. Acceleration, speed, handling, and braking are just as important as driver comfort, passenger legroom, and safety features. After all, it was BMW who created the first sports sedan, the BMW 700 and 1602/2002 models.

Those of us who have been on the BMW block for more than just a few months know that the heart of BMW’s are their engines. We also know that there is no better explanation of this than the epitome of BMW M cars as they were created in the late 1970’s and early 1980’s. At the time, the driving force behind this development was BMW’s newly formed Motorsports Division, BMW M GmbH. BMW Motorsport was able to pump out racing icons in its early inception, the legendary racing 3.0CSL, the rare and sporty E26 M1.

It was in this time period and shortly following that BMW was able to further develop street cars using the success of the motorsport homologation vehicles. With the on track success, BMW decided it was worth attempting to sell motorsport variants of their standard production models, and what a success they were.

The exclusive sport coupe M635CSi, and the E28 M5; the fastest 4 door saloon car in the world when launched, were the first Motorsports badged vehicles to grace public roads in the mid 1980’s. In addition to this plethora of legendary machines, was the now infamous E30 M3 that still holds the record for the winning-est car in racing history. The lineup from BMW Motorsport of the late 80’s was certainly an enviable one with the addition of the M3.

If you are like me, you may have started finding yourself having an appreciation for the heritage and lineage of these vehicles. Much the same way that one can trace the source of a lake back to a few individual streams or rivers, so too can one trace the source of the modern BMW engine. All of the vehicles mentioned above were related by a sequential timeline of engine development of BMW Motorsport. To really understand how the E30 M3 came to fruition, it really is imperative to know the history of these vehicles and how much more they have in common than one might realize.

Some of the following detail was found at the following link (although now it is unfortunately inactive): http://www.bimmernut.com/forum/5-series-bmw/20836-easter-special-history-bmw-motorsport-inc-factory-959bhp-m30-2.html

The History of the BMW M88 engine

Like you may have heard or read before, the S14 engine is the result of an almost 20 year evolution of engine development at BMW ///M GmbH. The intention of the article is not to explain the technical differences between the variants, but to give an overview of the evolution and to describe the legacy.

It all started in 1973 when BMW needed a more powerful engine for the competition CSL’s to compete with the Ford Capri’s. Until then, BMW via Schnitzer and Alpina raced the CSL’s with the M38 and M52 engines. These SOHC engines where based on the M06 engine from 1968. The M06 is the first version of the legendary engine family, which we all now know as the M30 big six from the E3/E9.

Linking the M30 with the M06 may seem confusing, but it is not. In the early 1980’s, BMW switched to a new system of coding their engines. Before then, an engine was designated by a three character long code and if applicable followed by a version (for example M90 or M49/1). The new engine coding used a six character long code and if applicable followed by one or more characters for engine specifics. The new engine code allowed BMW to specify its source (regular BMW or BMW Motorsport), the engine family and the displacement. Examples of the new engine codex are M30B35 and S62B50. The M06 engine from 1968 is coded according to the old coding system, while the M30B34 from 1985 is coded according to the new system. Some common engines with an ‘old’ ID code also received ‘new’ engine code. For instance the M06 is also know as the M30B25V with the V meaning “Vergasser” or Carburettor.

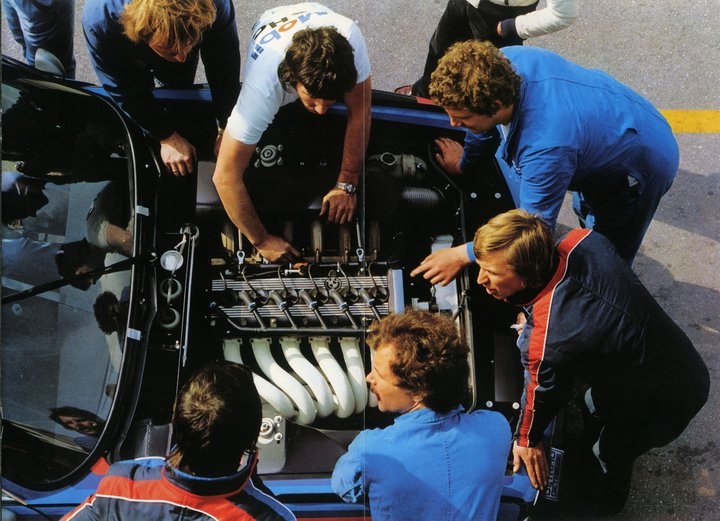

The M52 racing engine family created a base for the new 24-valve race engine coded M49. This new engine was developed by a new division lead by Jochen Neerpasch. Today we know that division as BMW Motorsport. Jochen Neerpasch managed to create a team with amongst others Paul Rosche, also known as “nocken Paul”. The cylinder head of the M49 engine is similar to the M12/2 formula II engine. This means that the camshafts are driven directly by the gear train. This valve-train was driven by a single timing chain via an intermediate shaft. Theoretically this allowed the head to rev over 9000RPM. But since the crankshaft is larger than the four-cylinder Formula II engine, 9000RPM was the limit for the group 5 engine.

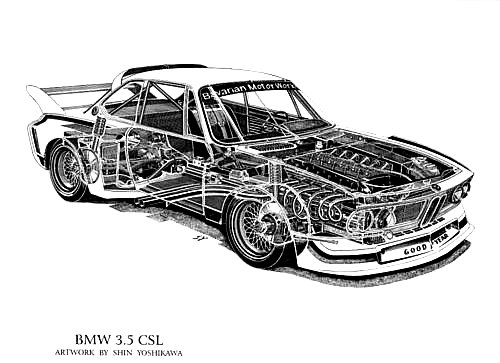

The M49 equipped E9 CSL won it’s first race in the European ETC series on the Salzburgrung in March 1974. A remarkable success, especially because it was also it’s racing debut. The oil crisis of 1973 and the commercial lack of interest for high performance cars (the E20 2002 turbo being a good example) slowed down the development of the E9 CSLs. Four E9 CSLs with M49 engines entered the American IMSA series in 1975. Also in 1976, BMW participated in the American IMSA series. During these two years, BMW won 7 races.

In Europe, there was hardly any real competition and when plans for a group 5 class for the 1975 season did not materialize, the European E9 CSL’s with M49 engines were sold off.

For the 1976 season, the oil crises was a few years back and BMW decided to enter the newly created group 5 series. By request of the factory, Josef Schnitzer further developed the M49 engine so it could be used for vertical installation in the CSL’s engine bay. Vertical installation allowed the use of larger exhaust headers, a more optimized inlet system and the installation of a more efficient cooling system. This engine was named M49/3 and yielded 465hp @ 8500RPM. But compared top the Porsche 935 turbo, the E9 CSL with the atmospheric M49/3 engine did not have a chance to compete. That is why in a later stage, twin turbo chargers where added. This was the fifth evolution of the M49 engine and was called M49/4. The M49/4 had a 300cc smaller displacement. With a bore of 94.0mm, the M49/3 only had 6.0 mm gap between the cylinders. For the non-turbo charged engines, this was enough, but turbo-charged engines produce much more heat, which has to be removed efficiently. Reducing the bore is one of the ways to achieve this. Even today, reducing the bore is a common practice to create a larger gap between the cylinder walls to create larger cooling channels within turbo charged engines. The four-valve M49/4 engine allowed a relatively low turbo pressure. Usually, a boost of 1.3bar (18PSI) was used to yield a neat 750hp @ 9000RPM. This high power output came with a relatively high reliability of the engine. Although the CSL gearbox was not designed for such a power, it held up rather well during the races. The practical experiences with the M49/4 engine provided a basis for the development of the later E26 ///M1.

All in all, the M49 engine and the E9 CSL where very successful in the Group 2 European Touring Car (ETC) series. From 1973-1976, BMW won the championship in these series. Although the last CSLs where made in 1974 and the last E9 coupe’s left the factory in December 1975, BMW Motorsport continued to support it in 1976, but could not continue in 1977 because it had become an obsolete model. This was a logic consequence of the introduction of the E24 6 series; using the CSL longer would not benefit the sales of the new coupe. Private teams continued to use the E9 CSL until 1978 and even managed to win the European Touring car Championship (ETC in 1977 and 1978).

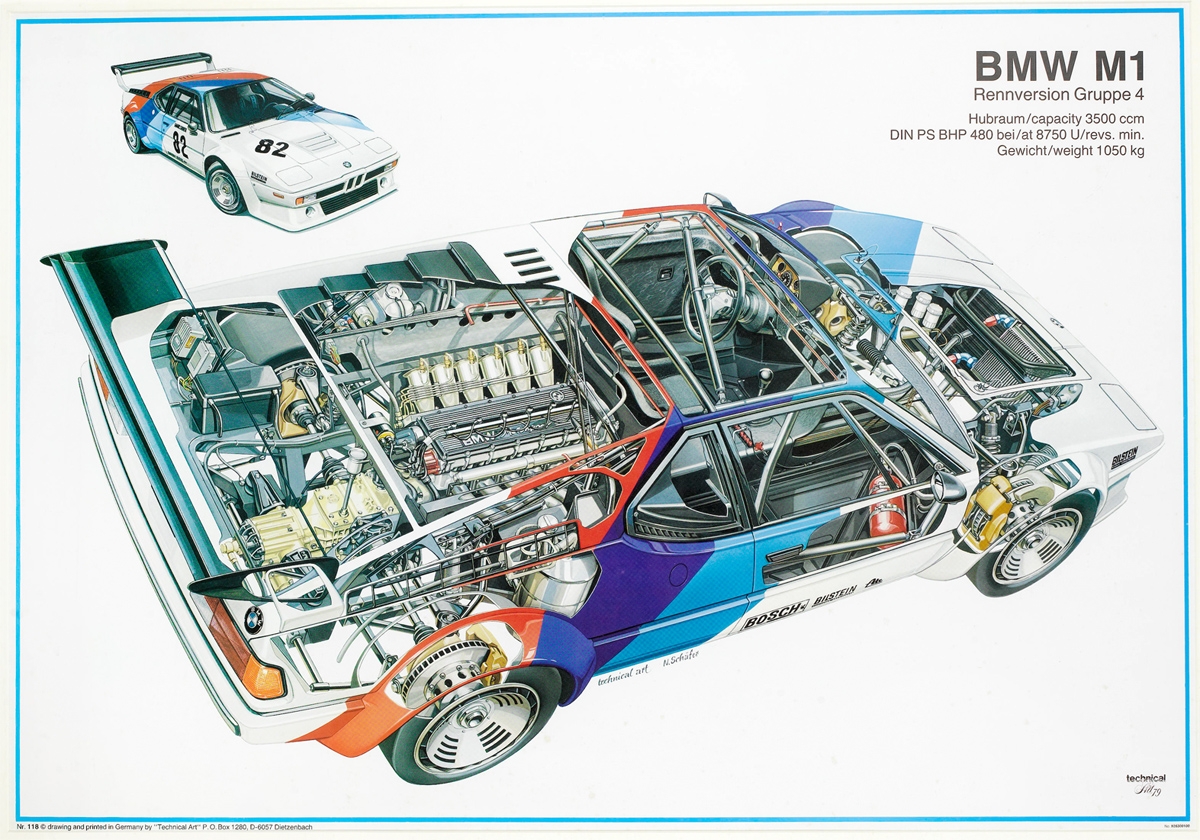

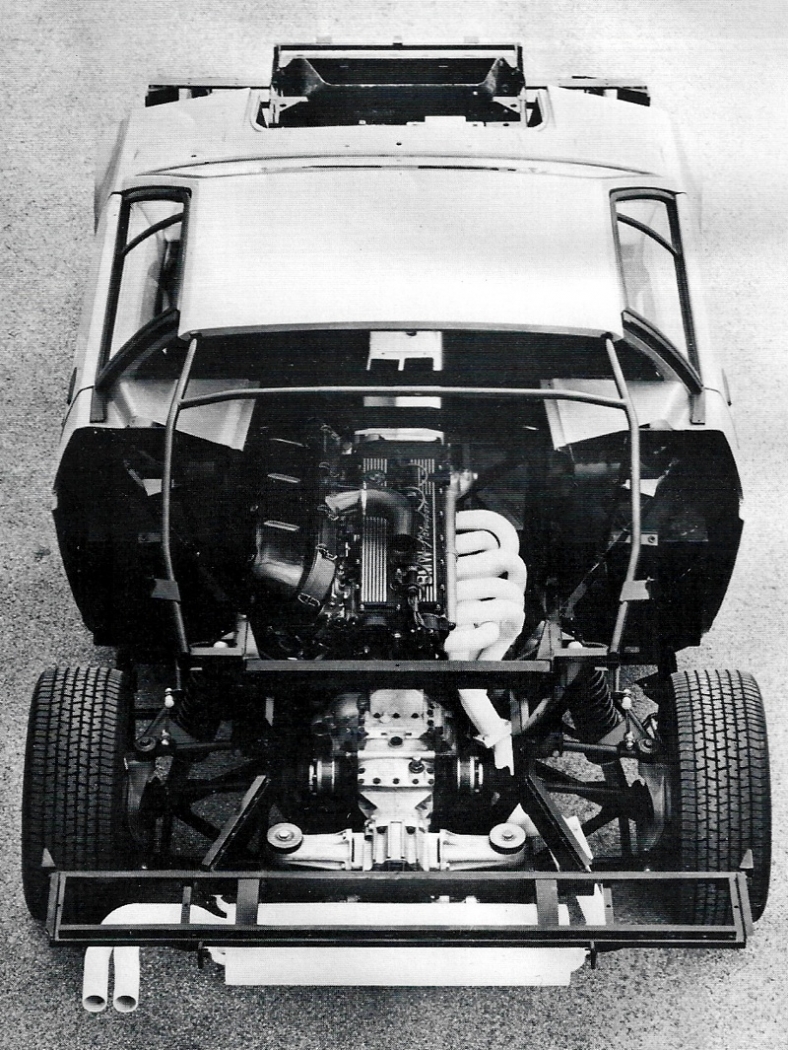

For the group 5 series, Jochen Neerpasch wanted a mid engined racing car. The development of the E26 ///M1 started in 1976. The idea was to develop a racecar first and a road car second. Since BMW did not have the capacity or the expertise to build a tube framed car, BMW Motorsport contacted Lamborghini to help with the development and the production of the chassis. But Lamborghini came into financial troubles and was not able to fulfill its commitments to BMW.

This delayed the production of the E26 ///M1 by more than a year and by the time the production of the ///M1 started, the rules for the group 5 touring car championship where changed and ruled out mid engined sports cars. At that time, Jochen Neerpasch had his new racecar, but could not use it. Max Mosley of the FIA came up with a brilliant idea. A new race class was established specifically for the ///M1. This new race class, the Group 4 Pro Car series was scheduled to take place before a Formula 1 race with a few formula 1 drivers and privateers.

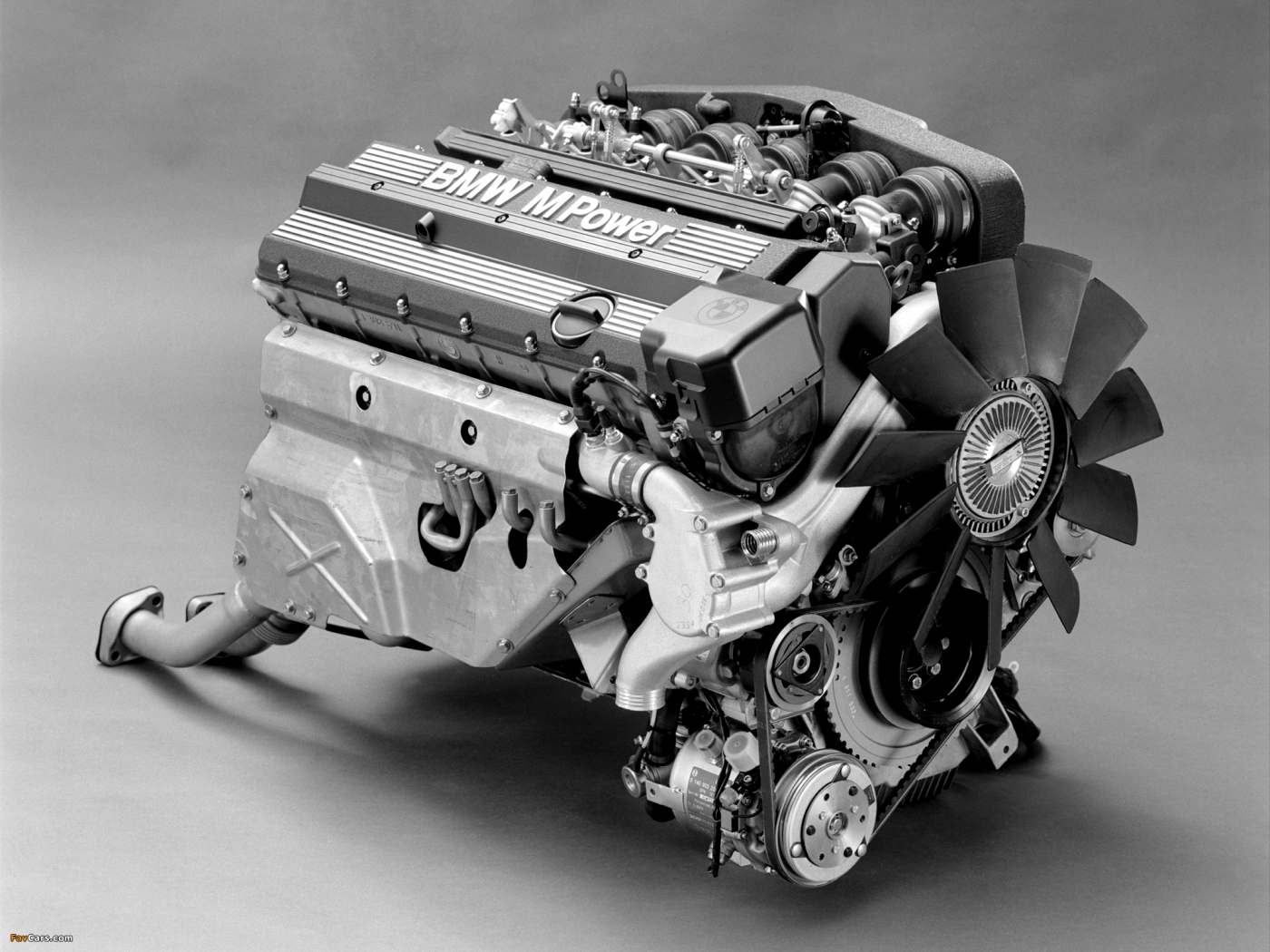

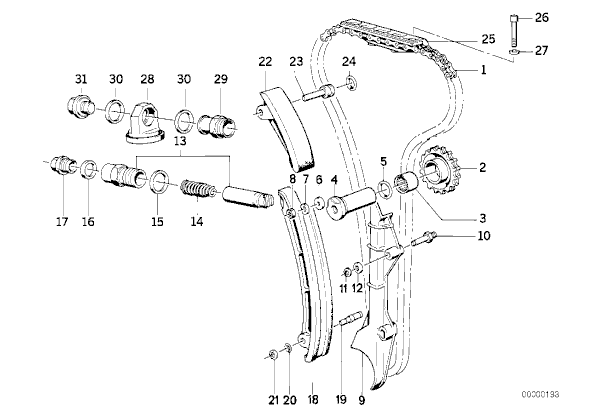

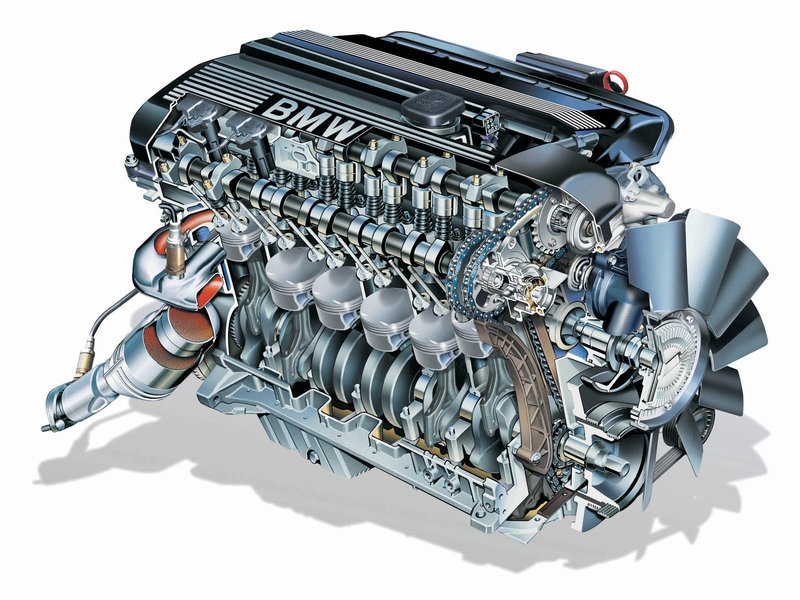

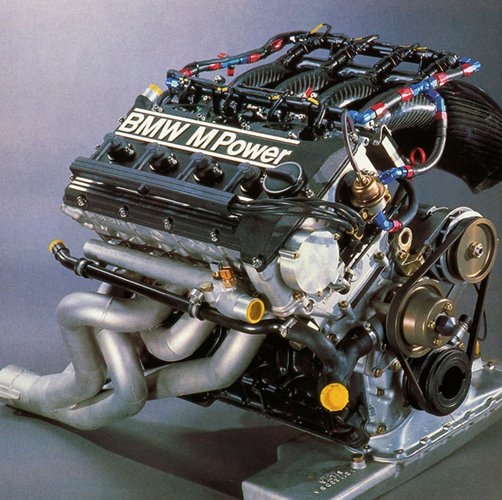

The engine for the ///M1 was an evolution of the M49 engine of which the development stopped in 1977. However the new engine M88 had significant changes to allow it to be used as a production engine for road cars. The same changes were made when building the E26 ///M1 for sale as a road car, a requirement for the group 4 regulations. The Group 4 rules required that 400 units of that same car would be made within one year. The direct drive of the camshafts by a gear train was abandoned for a direct chain drive to reduce the interior noise. Like the M49, the M88 engine also used a Kugelfisher mechanical fuel injection system. The cylinder head of the M88 consisted of two pieces. The lower piece contained the intake and exhaust ports, the valves and the spark plugs. The upper piece contains the buckets, shims, camshafts and bearings

Compared to the M49/3, the M88 had a slightly smaller displacement (3453cc). This was achieved by reducing the bore slightly to 93.4mm. However the stroke of the engine remained the same (84,0mm). To test if the M88 engine would be reliable for a production engine, BMW placed the existing SOHC drive train on the M88 cylinder block. This engine, called M90 used a regular Bosch L-Jetronic (predecessor of the Motronic) fuel injection system and yielded 218hp. This engine was utilized in the E12 M535i.

The road going ///M1 used the M88 engine. The M88 yields 277hp @ 6500RPM and 330nm @ 5500RPM. This was more then enough to propel the 1418kg sports car in a little more than 20sec to the 200km/h (125mph) mark .

Since the E26 ///M1 was designed for racing first, the M88 engine was heavily modified. For road use, the M88 is tuned to offer a good compromise between tractability, engine longevity and performance. Engine longevity was not that important for racing (besides, a lot more than 277hp was required for track use). New camshafts, larger valves, reshaped ports, throttle slides instead of butterflies, forged pistons and a completely different exhaust system helped to increase the power to almost 500bhp. For Group 5 purposes, two turbo chargers where added. This version is known as the M88/2. Depending on the boost pressure, the power output was between 850bhp and 950bhp.

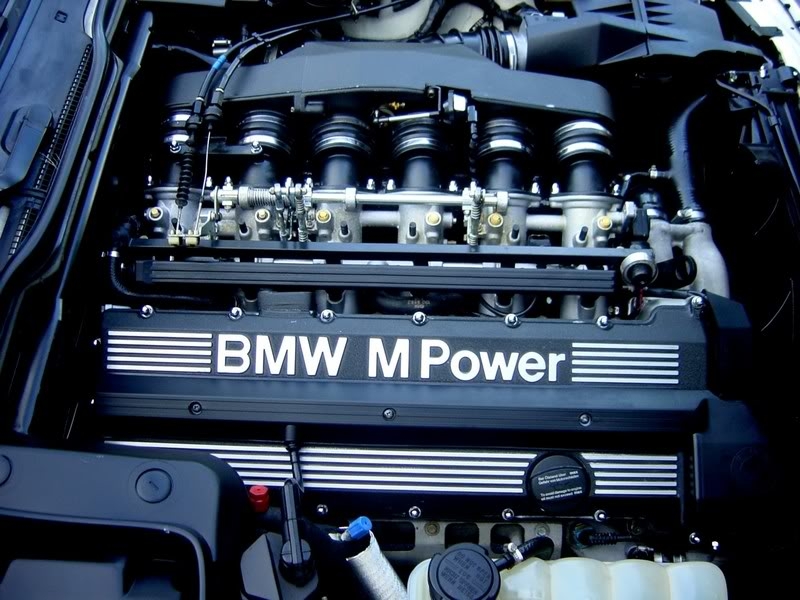

With the cease of the group 4 and group 5 races, BMW stopped using the M88 engine for racing purposes and concentrated on developing race cars on platform of the E21 (See The Flying Brick) and later the E30 3 series. But in 1983, the M88 was used one more time to power the new top model of BMW, the E24 ///M635CSI. The regular 635CSI lacked the power to compete with Porsche’s 928S and the Mercedes 500SEC. For the E24 ///M635CSI, the M88 was redesigned. The bore and stroke of the M88/3 engine remained the same as the M88. Also six individual butterfly valves where used for the M88/3. However, Bosch’s Motronic, the first digital controlled fuel-management system that was used in production cars, replaced the M88’s Kugelfisher fuel injection system. This allowed the compression ratio to rise to 10.5:1. Thanks to these changes, the power output rose to 286hp at 6500RPM. The torque rose slightly also to 340nm at 4500RPM. This was 500RPM lower than for the original M88 engine and this helped to improve the M88/3 abilities for daily use.

At the end of 1984, the M88/3 engine was also fitted in the E28 5 series. Unlike the ///M635CSI, the E28 version was not named ///M535I as this type was already given to another E28 with the M30B34 engine. Instead, the name ///M5 was chosen. Already from September 1984 till February 1985, a small number of E28 ///M5’s where hand build by BMW Motorsport for a happy few. It was not before February 1985 before the E28 ///M5 was introduced to the public. In the mid eighties, unleaded fuel and the use of catalytic converters became more and more common in Western Europe, especially in the environment oriented Swiss and Austrian market’s. The M88/3 engine did not have a catalyst. BMW did not want to be accused of being insensitive to the environment and decided against the introduction of the E28 ///M5 at the important Geneva car show. Instead, BMW released the E28 ///M5 at the Amsterdam car-show, reducing the potential risk of bad environmental publicity in the wider international press.

Despite that BMW already switched to a new engine codex in 1983, the new 24-valve engine kept the family code M88. It was not before 1986 when the S38 designation was used for the catalyst version of the M88/3. The S38 stands for, ‘S’ means that the engine is originated by BMW Motorsport, the ‘3’ means that it is derived from the M30 engine family and last but not least, the ‘8’ is chosen to make a reference to the legendary M88.

During the mid eighties, the ///M635CSI and the E28 ///M5 where only available in Western Europe. In the United States, there was a small but significant demand for these ‘European only’ cars. This gap in the United States market was served by ‘gray market’ importing companies. Realizing this, BMW North America introduced Motorsport versions of the E24 and E28 in 1987, but their specifications where changed to meet the demands of the American market. To meet US exhaust emission regulations of that time, the catalyst equipped S38B35 replaced the M88/3. The S38B35 kept the M88/3s bore, stroke and cylinder head, but to install a catalytic converter, the compression ratio decreased from 10.5:1 to 9.8:1. The equally tuned exhaust headers of the M88/3 where replaced by log headers. Al these changes decreased the engine performance. The S38B35 delivered 260hp and a torque of 330nm (243lb/ft) at 4500RPM. The US E28 ///M5 and E24 ///M6 also had more options fitted, many of which in Europe could only be bought by special order. As a result, the US cars where noticeable heavier than the European cars and this had an impact to the cars performance. The European E28 ///M5 can do the 0-100km/h (0-62mp/h) sprint in just 6.5sec, while the US version needs 0.3sec more.

For the US and Japanese markets, The ///M635CSI was renamed to ///M6, while in Europe the ///M635CSI designation remained. The distinction between the ///M6 and ///M635CSI is the engine. The ///M6 always contains the S38B35 engine, while the ///M635CSI can have both. Despite the catalyst, the majority of the E28 ///M5s and E24 ///M635CSI in Europe where equipped with the M88/3 engine, thus no catalyst.

The production of the last E28s ceased at the end of 1987 after which the E34 succeeded it. It was without any doubt that soon after the introduction of the E34, also a Motorsport version became available. The E34 ///M5 was available for the German market in September 1988. The engine which powered the E34 ///M5 is a further evolution of the S38B35 engine which powered the catalyst versions of both the E28 ///M5 and E24 ///M635CSI. The E24 ///M635CSI remained in production until its demise in spring 1989. During that time, the M88/3 and S38B35 engine were offered by BMW Motorsport alongside the S38B36. This was a major benefit for the last E24 ///M635CSI’s because in their last production months, both the M88/3 and S38B35 engines received the duplex timing chain of the S38B36 (a known weak point).

To create the S38B36, the S38B35 was stroked from 84.0mm to 86.0mm, the same as the M30B35 engine of 1989. The bore remained 93.4mm. This increased the total displacement to 3535cc. Actually, this is 3.5 liters and not 3.6 as the type designation indicates. However to make a distinction with the S38B35, the S38B36 engine was marked as a 3.6 liter engine. Not only was the stroke changed, but also the Compression ratio increased from 9.8:1 to 10.0:1. The S38B36 delivered 315hp @ 6900RPM and 360nm (269lb/ft) at 4750RPM, and was placed in the new E34 M5.

The intake received an electronically controlled RAM induction system to boost up the torque. A changeover valve varies the effective length of the induction system depending on load and engine speed. The changeover valve operates when the engine speed is below 4120RPM and full throttle or the engine speed is above 6720RPM and full throttle. The engine management remained the Bosch Motronic system, but instead of measuring the airflow with a valve, the S38B36 received an airflow measurement system based on a hot-wire sensor. In contrary to a conventional sensor with an air-valve and potentiometer, hot-wire sensors measures the mass of the air and since it is only a very thin wire, the air can flow to the intake-plenum without restriction- reducing flow resonance and noise.

To fulfill the exhaust emission regulations, a ceramic catalytic converter has been added to the exhaust system. To control the emissions at cold-engine start up an air injection feature for the exhaust has been added. This system injects air into the exhaust system to convert carbon monoxide into carbon dioxide and hydrogen into water. For Tropical regions, for instance the Middle East and south East Asia got a slightly different version of the S38B36. For these markets the compression ratio reduced to 9.2:1.

In 1991, the E34 ///M5 got competition by the Mercedes Benz 500E and of lesser importance, the Opel Lotus Omega and the BMW-Alpina B10 Bi-Turbo. Neither the Opel nor the Mercedes could match the ///M5 in character and driving abilities, but they where more powerful. The Opel Lotus Omega has a twin turbocharged 3.6 litre 24-valve engine and was (a cheaper) competitor for Alpina’s B10 Biturbo. The 500E however was directly positioned as a competitor to the ///M5. Compared to the E34 ///M5, the 500Es strength was its torque (the a 5.0 liter 32-valve V8 produced 480Nm). The 500E was approximately 100kg heavier than the E34 ///M5, and was a polished autobahn performer. In all other areas the E34 ///M5 chassis performed better however. Ever keen to compete against Mercedes, BMW Motorsport redesigned the S38 to gain back the “fastest 4 door saloon” title.

The bore and stroke where increased one more time. As a result the displacement grew to 3795cc. Another significant change is the compression ratio that was increased to 10.5:1. The intake and exhaust ports increased in size also and each spark plug got it’s own HV coil which eliminated the distributor rotor and the high voltage wiring. A smaller and lighter Emitec metallic type replaced the ceramic catalytic converter. The main advantage of the Emitec metallic converter is that it increases the flow of the exhaust gasses. The Bosch Motronic 1.2 fuel management system was changed for the Motronic 3.3 system of the same manufacturer that also includes the resonance flap control. This feature is the same as on the S38B36, but with an extra switch-point at 2480RPM.

The S38B38 was the last evolution within the S38 engine family and delivered 347hp @ 6900RPM and 409nm torque at 4750RPM. All these changes stretched the S38 to its limit. The web spacing between two cylinders with 5.4mm is extremely narrow. This is 0.6mm less that the M49/3 racing engine. The S38B38 engine remained in production until the summer of 1995 when the last E34 ///M5s left the production facility in Garching.

For the Swiss and Austrian market, the S38B38s where fitted with Ceramic catalytic converter and the smaller exhaust manifolds (80mm vs. 90mm) of the S38B36 engine. As a result, the Austrian and Swiss version did not deliver 347hp, but 327hp.

Post S38 period

S50B30, S50B32, S50B30 US and S52B32

In 1992, BMW introduced the E36 ///M3 coupe with the S50B30 engine. The S50B30 is based on the smaller M50 engine family, but had a completely new 24-valve head. All in the ///M tradition, this engine also has 6 individual butterfly valves. Completely new was the VANOS system to vary the intake camshaft and thus the timing of the intake valves. This means more torque at lower revs. The S50B30 engine measured 2990cc and delivered 286bhp @ 7000RPM and 320nm @ 3700RPM. The US did not get this expensive engine as it did not comply with emissions regulations. Essentially the S50B30 US is just a bored and stroked M50B25 with VANOS, meaning they skipped the 6 throttle bodies and the expensive head construction resulting in an overall power loss of 46hp.

In 1995, the S50B30 was bored and stroked one more time to 3201cc. Other significant changes are that the DME was now a system developed by BMW and Siemens. Also the exhaust camshaft timing is controlled by VANOS. Power rose to 321hp at a staggeringly high 7600RPM. The US again got a detuned version (E36 M3) without the S50B32’s expensive cylinder head and intake system.

Compared to the S50B30 US, the S52B32 delivered the same power, but more torque at lower revs. It was found in the later model E36 M3’s and is a great engine.

For continued model evolution was the E46 ///M3 of 2000. This engine was completely redesigned and thus called S54B32. It shares few major components with the S50 and differences include:

- Increased cylinder bore to 87 mm (from 86.4 mm) for a new total displacement of 3,246 cc (from 3,201 cc)

- Modified camshafts

- High pressure Double VANOS continuously variable valve timing system with faster operation at high rpm

- Increased compression to 11.5:1 (from 11.3:1)

- More advanced BMW/Siemens MSS 54 engine management control

- Finger-type rocker arms for reduced reciprocating mass and friction

- One-piece aluminum head casting for lighter weight

- Scavenging oil pump to maintain pressure during heavy cornering

Like the S38B38, this engine is also stretched to its limit. BMW was able to squeeze a slight bit more from the engine for its placement into the E46 M3 CSL, but mostly the differences are in weight and hardware components and materials.

S62B50

When the E39 succeeded the E34 in 1996, it took almost three years before it was succeeded by the E39 ///M5. Originally, BMW did not plan a Motorsport version of the E39 as it felt that the E39 540I and the E36 ///M3 4 door would fulfill the demands of the E34 ///M5 owners. However the ///M5 customers did not buy that, probably since neither the E36 ///M3 or the E39 540I are really exclusive cars. In 1997 BMW realized this and started to develop the third generation of the ///M5. The first prototype was shown to journalists on the IAA car-show of 1997, but it was not before December 1998 that the first E39 ///M5s where delivered to customers. Instead of an inline six, BMW used the M62 V8 engine as the basis for the S62B50 power plant with 400bhp. The E39 ///M5 turned out as a very successful car, especially in the USA. Already in the summer of 2001, BMW had manufactured more E39 ///M5’s than E34 ///M5’s in a seven-year period!

Unlike the E28 and E34 ///M5, the E39 ///M5 was not hand build in Garching anymore, but manufactured on the E39 production line in Dingolfing. Thanks to this, the German MSRP of DM140000 for the E39 ///M5 in 1998 was almost the same as the customer cost for the last E34 ///M5 in 1995.

Developments related the S38

M90

The M90 was the first road going BMW engine with 3.5 litre displacement. Originally this engine was used to test if the M88 engine was reliable with the narrow web spacing of 6.6mm. This means that this engine has exactly the same bore and stroke as the M88 and is directly related. However instead of a DOHC cylinder head with 24 valves, BMW used the SOHC cylinder head with 12 valves. The use of an electronically controlled fuel management system (Bosch LE-Jetronic) allowed a slightly higher compression of 9.3:1. Strictly, the M90 engine is not an M production engine although the E12 ///M535I in which it is used is a real M car. Until 1981, the M90 engine was used for the early 635CSI and the very rare and delectable E12 ///M535I from 1980 (although the E12 530MLE is more unique).

In 1981 and 1982, Alpina used the last batch of the M90 engine to power the last versions of the B7 turbo versions of the E12 sedan and E24 coupe. For the B7S turbo, the M90 has been modified extensively to allow the use of a turbocharger. The B7S delivered 330hp @ 5800RPM and 500nm @3000RPM. During 1981 and 1982, Alpina only made 60 E12 sedans and 30 E24 coupe’s in the B7S version.

M30B35

To improve the reliability for road use, BMW redesigned the M90 engine in 1981. This engine, called M30B35 was slightly different. Compared to the M90, the M30B35 has a larger stroke (86,0mm), but a smaller bore (92,5mm). The use of a digital controlled fuel management system (DME) allowed to increase the compression ratio from 9,1:1 to 10,0:1. Although the engine capacity decreased slightly (3430cc vs. 3453cc), power and torque remained almost the same. This engine was the final iteration of the BMW M30, which was originally developed in the late 1960’s. The engine management was able to maximize output with the use of Motronic 1.3 and the Mass Air Flow sensor.

This engine was also used a lot by tuners and the tuners with a manufacturer status such as Hartge and Alpina. Alpina examples are the E28 B7 turbo, the E24/1 B7 turbo, the E28 B9, the E30 B6(S), the E28 B10 3.5, and the E34 B10 3.5 and last but not least the E34 B10 Biturbo. In 1993, the last 50 M30B35 engines where delivered to Alpina for the last 50 B10 Bi-Turbos.

M88 engine derivatives

S14B20, S14B23 and S14B25

This engine family was developed in the early 1980’s for use within the E30 series where it had to power the new BMW touring car racer, the E30 ///M3. It has a very interesting history as the engine block was based on the cast iron M10 engine family (BMW 02 series). The cylinder centres of the M10 (at 100mm) are the same as on the M88 so this allowed BMW Motorsport to simply cut off two cylinders of the existing M88 cylinder head. The basic engine specifiecations echoed the M88. The bore (93.4mm), stroke (84.0mm) and compression ratio (10.5:1) for the S14B23 where chosen exactly the same as the M88/3 for simplicity, which then created a displacement of 2302cc. Enough to deliver 200hp @ 6750RPM and 176lb/ft of torque at 4750RPM. With catalyst this engine delivered 195hp and 169lb/ft @ 4750RPM.

In Italy, there was the 320iS, a deviation of the E30 ///M3 to avoid the huge Italian taxes for road cars above two liters. The 320iS simply used the 325iS-body style, but powered by an S14B20 engine. The S14B20 has the same bore as the S14B23, but a smaller stroke (72.6mm) resulting in a displacement of 1990cc. A compression ratio of 10.8:1 still allowed 192hp at a stunning 6900RPM. More than 3000 320iS cars found their way to Italian customers.

In September 986, the first E30 ///M3’s where sold to their first customers and within the first year, more than 5000 units where sold to meet the FISA Group A rules. 2396 where build in 1986 and 6396 in 1987 and thus easily satisfying the rule makers. It did not take long before the first evolution versions arrived.

For the evolution II models of 1988, BMW Motorsport fitted other pistons to increase the compression ratio to 11.0:0. The displacement and the cylinder head construction are exactly the same as the regular 2.3 liter. But now 220hp and 181lb/ft where available. In a later stage, this engine with a catalyst became available for the E30 ///M3 Cecotto and Ravaglia editions.

The last version of the S14 engine is the S14B25. An increased bore (now 95.5mm) and stroke (87.0mm) increased the displacement to 2483cc. The compression ratio remained 10.5:1. At 7000RPM this is enough for 238 hp and 177lb/ft @ 4750RPM. This engine is used for the last 600 ///M30 evolution III, the most delectable of all ///M3s.

The primary purpose for the S14 engine was to power the E30 ///M3 touring car racer which raced in different European touring car series of which the most important was the DTM (German Touring car championship). For these many engine versions where made (S14/1 till S14/7).

When the production of the E30 ///M3 ceased in March 1990, more than 17000 of these cars have been made and found their way to very happy owners. In terms of nimbleness, driving satisfaction and performance this may be the ultimate ///M car ever made (largely due to a great chassis and an excellent engine).

Tuner Efforts

Although the engines from the S38 and M88 have a high state of tune when they left the factory, for some this was not enough. Especially in the USA, there was a demand for even higher power output. A few enthusiastic companies served this niche in the market and offered tuning kit’s that could be acquired separately or together as a complete package. In Europe, BMW’s where mostly tuned as a complete package. Good examples are companies like Alpina and Hartge. Hartge actually did tune the S38 engine family, but Alpina never touched a BMW-Motorsport engine Those iterations mentioned above, were only M coded engines and not S coded engines (BMW Motorsport). Although many companies actually tuned the S38, it is undoable to describe all efforts in this field.

Dinan-BMW

Steve Dinan grounded his California based company, almost 35 years ago. Unlike many European counterparts, Dinan offers their performance program as kits that can be bought separately or as a complete package. In 1986, Dinan developed a turbocharged version of the S38B35 engine. For the E34 ///M5’s S38B36, Dinan developed several tuning programs known as Stages. Dinan’s program starts with a modified DME, other cam sprockets to retard the timing for more torque in the low en mid range and a stroker kit to increase the S38B36 to 3,9 liters (3880cc). Added to that, you can buy the companies modified camshafts. In the strongest program, Dinan claims 402bhp (SAE).

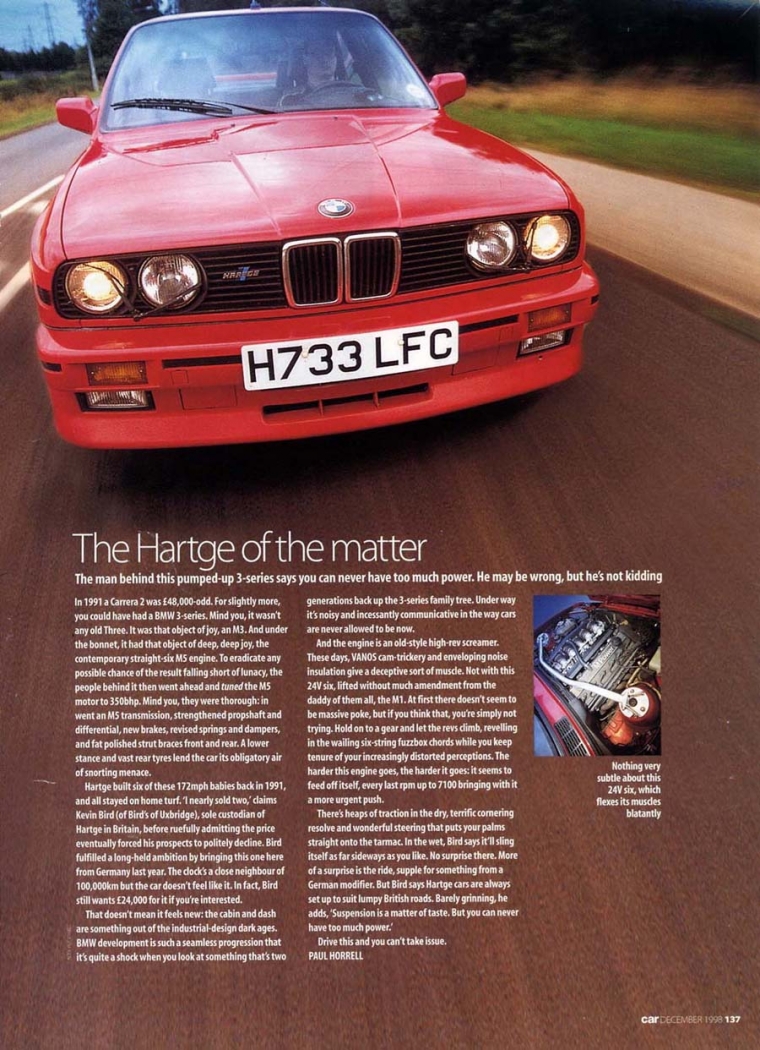

Hartge

In Europe, the S38 and M88 were less prone to tuner efforts. A Company that did was Hartge. Hartge fitted hotter cams to the M88/3 and reprogrammed the DME and added different cams. With 330hp @ 7000RPM and 260lb/ft @ 3500RPM, this is a serious improvement. This engine was fitted in amongst others the Hartge H5SP-24, their version of the E28 M5. Hartge also used this engine for the H36, an E30 ///M3 equiped with the Hartge’s modified M88/3. Only six of these beasts where ever built.

After reviewing in detail the history of some of these BMW engines, it is obvious to see how interconnected the BMW engines are to each other and to racing variants. This is the reason BMW has been been able to stay ahead of the curve regarding engine development of their vehicles. It is also clear that these engines had a direct impact with the direction of vehicles being manufactured.

Notes:

1. All power figures in the article are DIN. According to SAE the power is slightly smaller.

2. The torque in lb./ft can be calculated by multiplying the nm. Figure with 0.73529

Latest posts by Tom Schultz test #2 (see all)

- 2024 Durango Event - 24 February, 2024

- Drive 4 Corners 2022 Low-Key Event Concluded - 1 September, 2022

- Drive 4 Corners 2022 Informal Event Planned! - 6 June, 2022